NEO Battery Materials Ltd.: Transforming the Future of Electric Vehicles

As the world becomes increasingly conscious of climate change, the demand for electric vehicles (EVs) continues to rise. However, limited battery capacity, short driving ranges, slow charging times, and high EV prices remain a major challenge for the industry. That’s where NEO Battery Materials Ltd. comes in. Based in Vancouver, the Company is dedicated to developing the next generation of lithium-ion batteries that will power the EVs of the future. Their groundbreaking work in silicon anode materialsis set to transform the EV industry by increasing the EV driving range by more than 20%, enabling ultra-fast charging, and cutting costs, all at the same time.

700-838 West Hastings Street

Vancouver, British Columbia

Canada V6C 0A6

NEO’s mission is to help accelerate the mass adoption of electric vehicles through lower-cost, longer-running, and faster-charging lithium-ion batteries by using a new, unique battery material – silicon anodes.

Today, virtually all lithium-ion batteries use graphite as the anode material, which is one of the four core battery materials. Graphite contributes to three prominent pain points for the battery: 1) inflating EV prices from rising demand and insufficient supply, 2) slow charging time, and 3) limited EV range that causes “range anxiety”.

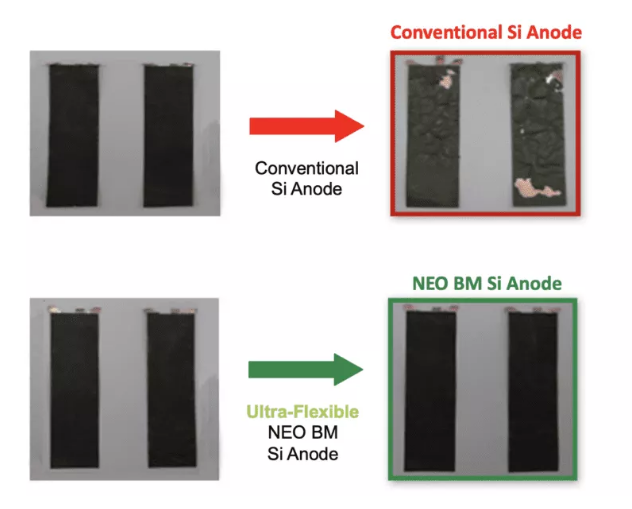

Fortunately, a promising catch-allsolution exists to significantly increase the EV driving range and to decrease the charging time ofbatteries –silicon. However, silicon faces a volume expansion problem, growing 300% from its original size during charging. If unresolved, the silicon breaks down in the batteryand rather poses safety hazards during operation.

At NEO Battery Materials, the Company has developed a robustmanufacturing technology to effectively resolve silicon’s volume expansion problem, enabling commercial and automotive-level useof silicon anodes.With over 60 relationships established including global battery manufacturers and EV automakers, NEO Battery is ongoing 20+ active material evaluations to achieve milestone deals and strategic partnerships in the near-term. Constructing a commercial plant in South Korea, the Company aims to become one of the top 10 global suppliers of silicon anodes.

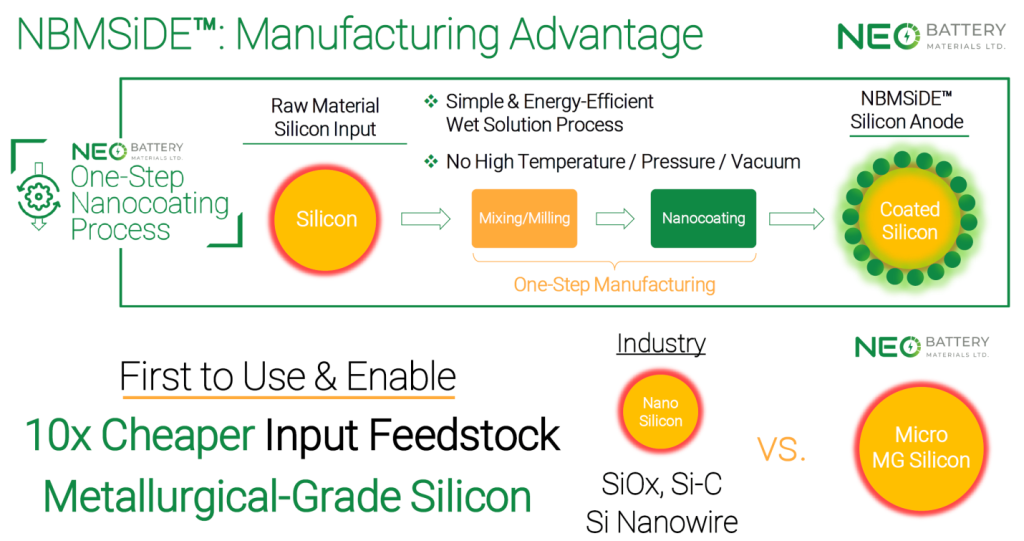

The Cost-Effective One-Step Manufacturing Process

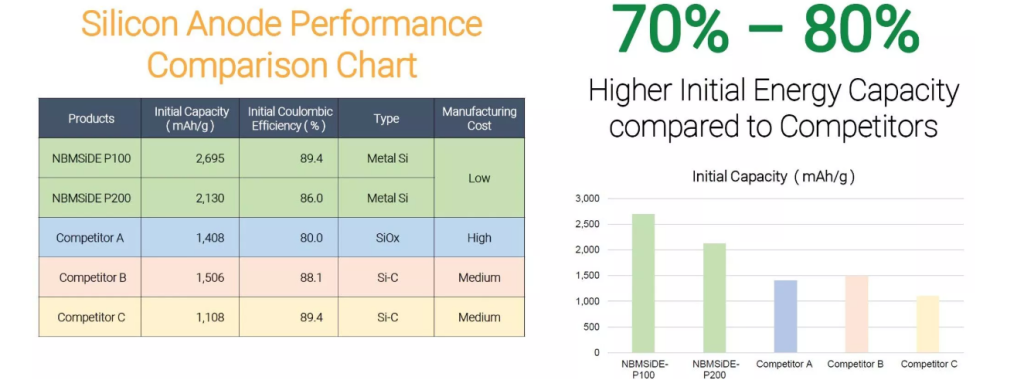

With a management and engineering team from global battery manufacturers like LG Chem and Samsung SDI, NEO Battery Materials has developed a transformative manufacturing process to produce silicon anodes. Coupled with using the cheapest raw materials, the Company will be one of the lowest-cost producers, providing products that are more than 70% cheaper than competitors’ options.

Competitors actively use energy-intensive and inefficient systems such as high temperature, high pressure, and vacuums, significantly driving up the productioncost. However, NEO Battery’s proprietary process is energy-efficient and inexpensive, producing silicon anodes in a single manufacturing step.

Being the first mover to use a 10 times cheaper raw material called metallurgical-grade silicon, NEO Battery will be able to supply silicon anodes at more than half the cost compared to current silicon anode technologies.

Process Advantage

Cost-Effective and Efficient One-Pot, Single-Step Nanocoating Process

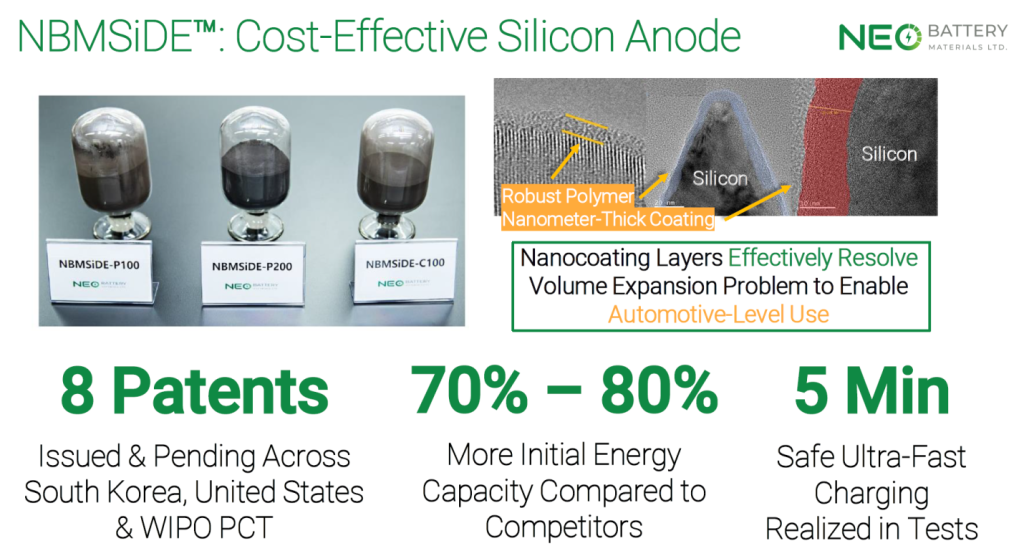

NEO Silicon Anode Nanocoating Technology

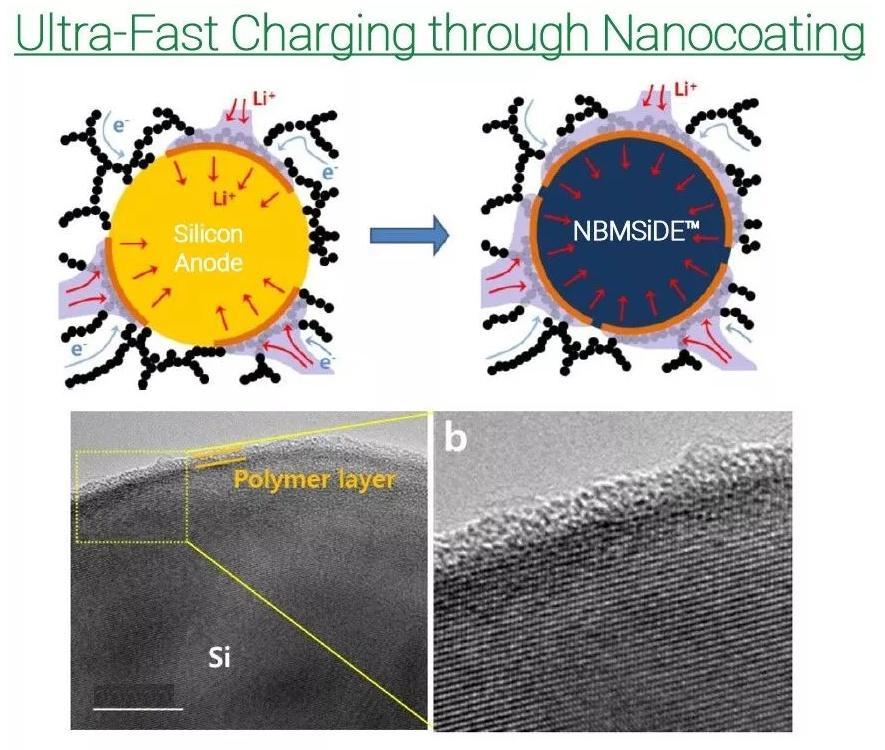

NEO Battery Materials’ patented technology utilizes strong, robust nanocoating materials to effectively resolve the volume expansion problem of silicon. The Company’s technology effectively controls and suppresses volumeexpansion by encasing the silicon inside a protective matrix, allowing the long-term cycling performance. Currently, 8 patents are issued and pending with regards to the manufacturing technology and materials in South Korea, U.S., and the WIPO.

The three types of products, NBMSiDE-P100, NBMSiDE-P200, and NBMSiDE-C100 are manufactured through NEO’s proprietary nanocoating technology and are based on metallurgical-grade silicon with purities of at least 99.9%. NEO’s products have all achieved an initial coulombic efficiency (ICE) greater than 86%, and high specific capacity (>2,500 mAh/g). In addition, an ICE of 92% or higher can be attained when NEO’s silicon is mixed with existing graphite anodes. NEO’s technology significantly improves the life span and performance stability compared to conventional, unprocessed silicon anodes. The Company is on schedule to target commercial-scale production of these materials by the first half of 2024.

Performance Advantage I

Boosting Energy Density & Significantly Increasing Battery Life Cycle

Performance Advantage II

Ultra-Flexibility to Counter Volume Expansion

Performance Advantage III

Ultra-Fast Charging Capability through Better Wettability and Superior Affinity to Liquid Carbonate Electrolytes

Corporate Social Responsibility

NEO Battery Materials Ltd. is committed to Corporate Social Responsibility (CSR) and has implemented several initiatives to ensure that it operates in a sustainable and responsible manner. Some of the ways in which NEO Battery Materials is fulfilling its obligations towards CSR are:

Environmental Impact

NEO Battery Materials recognizes its responsibility to minimize its impact on the environment and has implemented several measures to reduce its carbon footprint. The Company has developed proprietary technology to improve the efficiency of battery materials production, which reduces waste and energy consumption. Also, NEO Battery Materials has ongoing research projects aimed at developing more environmental-friendly battery materials. As an on-going initiative, the Company is aiming to recycle silicon waste produced by the solar and semiconductor industries, enabling a closed-loop system for manufacturing NEO’s silicon anodes.

Social Initiatives

NEO Battery Materials is committed to making a positive impact on society and supports a number of social initiatives. The Company invests in research and development projects aimed at developing technology solutions for renewable energy and reducing carbon emissions. Also, NEO Battery Materials collaborates with local communities in both South Korea and the U.S. to identify and address social issues.

Long-Term Sustainability

NEO Battery Materials is focused on building a sustainable future. The company invests heavily in R&D to develop innovative technologies that can contribute to sustainable energy solutions. By doing so, NEO Battery Materials is not only ensuring its own sustainability but also contributing to the sustainability of the planet.

Employee Welfare

NEO Battery Materials recognizes the importance of taking care of its employees. The company provides a safe and healthy work environment and offers opportunities for career growth and development. NEO Battery Materials also promotes work-life balance by providing flexible work arrangements and other benefits.

NEWS

Historical Price Performance

Company Info

Press Release

Compare with another sector

Let’s now look at how NEO Battery Materials Ltd. (TSXV: NBM) (OTCQB: NBMFF) and comparison to some other players in the battery industry.

| Company Name | Symbol | Price | Market Cap (USD) |

|---|---|---|---|

| NBM | 145,578 | ||

| Lithium Americas Corp. | LAC | 6.845 | 155,439 |

| Albemarle Corporation | ALB | 87.64 | 145,565 |

| LTHM | 145,560 | ||

| Tesla Inc. | TSLA | 435.97 | 155,439 |

Management Team

Spencer Sung Bum Huh, BEc.

Director, President and Chief Executive Officer

Spencer Sung Bum Huh, a Korea University graduate, is a seasoned financial professional with 25+ yea

View MoreDr. Seong Gi Kim

Chief Technology Officer

Dr. Kim was the Executive VP and Head of R&D at Hanwha Solutions' Advanced Materials Division, where

View MoreDr. Basudev Swain

Chief Science Officer

Dr. Swain has 20+ years of experience in lithium-ion battery materials and recycling process develop

View MoreSung Rock Hwang

Director, Chief Operating Officer and Senior Vice President

Mr. Sung Rock Hwang has 30+ years of experience at Samsung SDI, holding various positions including

View MoreSung Rock Hwang

Director, Chief Operating Officer and Senior Vice President

Mr. Sung Rock Hwang has 30+ years of experience at Samsung SDI, holding various positions including

View More| a | 1 |

| s | 2 |

| x | 3 |

| d | 4 |

| f | 5 |